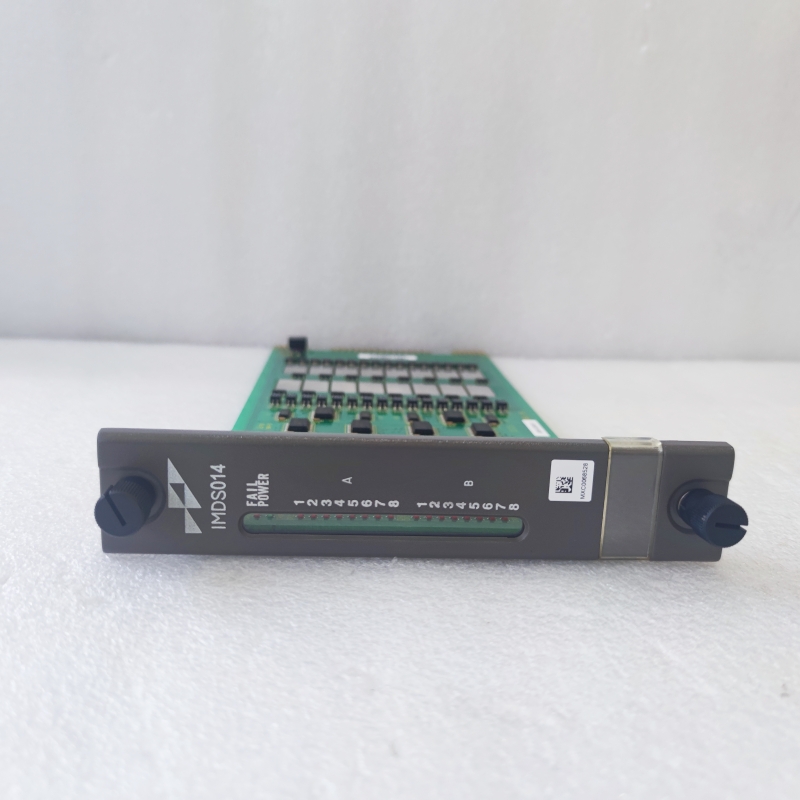

Description

ABB 1MRK002246-BD

The ABB 1MRK002246-BD is part of the Relion 670 series, specifically designed for protection and control in power systems. Below are the key technical parameters for this device:

General Information:

- Product Series: Relion 670

- Device Type: Protection and Control IED (Intelligent Electronic Device)

- Application: Used in substation automation, feeder protection, and power system management.

Key Technical Parameters:

1. Power Supply:

-

- Rated Voltage: Typically 24–48 V DC or 110–250 V DC/AC (varies by model)

- Power Consumption: ~10–20 W (depends on configuration)

2. Communication Interfaces:

-

- IEC 61850 (Standard for substation communication)

- IEC 60870-5-103/104 (Telecontrol protocols)

- DNP3.0 (Distributed Network Protocol)

- Modbus RTU/TCP (Serial/Ethernet communication)

- Ethernet Ports: Typically 2–4 ports (for station bus & process bus)

3. Protection Functions:

-

- Overcurrent protection (ANSI 50/51, 50N/51N)

- Directional overcurrent (ANSI 67/67N)

- Earth fault protection

- Voltage protection (ANSI 27/59)

- Frequency protection (ANSI 81O/U)

- Breaker failure protection (ANSI 50BF)

4. Control & Monitoring:

-

- Circuit breaker control

- Auto-reclosing (ANSI 79)

- Synchrocheck (ANSI 25)

- Load shedding

5. Inputs/Outputs:

-

- Binary Inputs: Typically 16–32 (24/48 V DC or 110/220 V DC)

- Binary Outputs (Relays): Typically 8–16 (configurable for trip/alarm)

- Analog Inputs: For voltage/current measurements (depends on module)

6. Environmental Conditions:

-

- Operating Temperature: -25°C to +70°C

- Storage Temperature: -40°C to +85°C

- Humidity: Up to 95% (non-condensing)

7. Certifications & Standards:

-

- IEC 60255 (Protection relays standards)

- IEEE C37.90 (Surge withstand capability)

- EMC Compliance: IEC 61000-4 (Immunity to disturbances)

Additional Features:

- HMI (Human-Machine Interface): LCD display for local configuration

- Time Synchronization: IRIG-B or PTP (IEEE 1588)

- Cybersecurity: Supports secure communication (IEC 62351)

.jpg)

Main Brand:

ABB Allen-Bradley Alstom Bently Emerson Foxboro

GE MOOG Schneider Woodward HIMA Honeywell

. Sales Director:Tara

·Tel: + 86-13806028623

·Whatsapp:+86-13806028623

·Email: x13806028623@gmail.com

·Ship to you via DHL/TNT/UPS/EMS/Fedex

First hand source, affordable price. Spot inventory!

ABB 5SHY series hot selling//large inventory//brand new//affordable price

| 5SHY4045L0006 3BHB030310R0001 |

| 5SHY3545L0010 3BHB013088R0001 3BHE009681R0101 GVC750BE101 |

| 5SHY3545L0009 3BHB013085R0001 3BHE009681R0101 GVC750BE101 |

| 5SHY3545L0016 3BHB020720R0002 3BHE019719R0101 GVC736BE101 |

| 5SHY3545L0009 |

| 5SHY3545L0003 |

| 5SHY35L4503 3BHB004693R0001 3BHB004692R0002 5SXE01-0127 |

| 5SHY35L4510 |

| 5SHY35L4520 5SXE10-0181 AC10272001R0101 |

| 5SHY5045L0020 |

What is a DCS?

A Distributed Control System (DCS) is a sophisticated, computer-based control system designed to automate, monitor, and manage complex industrial processes. It is widely used in large-scale industrial facilities such as refineries, power plants, chemical plants, and paper mills, where precision, reliability, and scalability are critical.

How Does a DCS Work?

A DCS is composed of several interconnected components that work seamlessly to ensure efficient process control. Here’s a breakdown of its key elements:

- Controllers:

These are the “brains” of the system. Controllers receive data from sensors, process it using pre-programmed logic, and send output signals to actuators to maintain optimal process conditions. - Sensors:

Sensors act as the “eyes and ears” of the system, measuring critical physical parameters such as temperature, pressure, flow rate, and level. This real-time data is essential for accurate control. - Actuators:

Actuators are the “muscles” of the system. They execute physical actions based on controller commands, such as opening/closing valves, starting/stopping motors, or adjusting dampers. - Operator Stations:

These serve as the human-machine interface (HMI), allowing operators to monitor the process, adjust setpoints, and troubleshoot issues. Modern DCS systems often feature intuitive graphical interfaces for ease of use. - Communication Network:

The backbone of the DCS, this network connects all components, enabling seamless data exchange and coordination. It ensures that every part of the system works in harmony, even across large industrial sites.

Why is a DCS Important?

- Centralized Control with Distributed Execution: A DCS allows for centralized monitoring while distributing control functions across multiple controllers, reducing the risk of system-wide failures.

- Scalability: It can easily expand to accommodate growing operational needs.

- Reliability: Redundant systems and fail-safes ensure continuous operation, even in critical environments.

- Efficiency: Optimizes processes, reduces waste, and improves overall productivity.

ABB: Pioneering Electrification & Automation

1. Company Profile

- ABB(Asea Brown Boveri), a Swiss-Swedish multinational headquartered in Zurich, is listed on the Zurich, Stockholm, and NYSE stock exchanges. Formed in 1988 through the merger of ASEA (Sweden) and BBC Brown Boveri (Switzerland), it combines over a century of industrial expertise.

- Core Competencies

- Key Sectors: Delivers cutting-edge electrification, automation, and robotics solutions for industries, energy, transportation, and infrastructure.

- Robotics Spin-off: Announced plans (April 2025) to list its robotics division (2024 revenue: $2.3B) separately by 2026—currently the world’s #2 player after Japan’s Fanuc.

- Innovation & Impact

- Technology Leadership: Global leader in online analytical instruments, e.g., Fourier-transform near-infrared analyzers (6,000+ installations worldwide).

- Sustainability: Drives energy efficiency and circular economy practices to minimize environmental footprints.

ABB: Powering Industrial Transformation

- Corporate Identity

- Formation: 1988 merger of ASEA (1883) and BBC Brown Boveri (1891)

- HQ: Zurich, Switzerland

- Scale: Operates in 100+ countries with ~105,000 employees

- Market Presence: Dual-listed in Europe/North America

2. Strategic Business Units

| Division | Market Position | Key Initiative |

| Electrification | #1 in EV charging infrastructure | Grid digitalization |

| Industrial Automation | Top 3 globally | AI-powered process optimization |

| Robotics & Discrete Automation | #2 worldwide | *2026 spin-off (Post-IPO valuation est. $7-9B)* |

Robotics Spin-off Context: $2.3B revenue segment (2024), targeting public listing to accelerate growth vs. Fanuc (#1).

3. Technology & Sustainability Edge

- Innovation Engine:

- 🏆 World’s largest installer of FT-NIR analyzers(6,000+ units)

- 💡 5,500+ patents held in electrification/automation

4. Market Footprint

- Key Sectors:

- Energy Transition: Renewables integration, HVDC systems

- Transport: Rail electrification, port automation

- Manufacturing: Collaborative robotics (YuMi® series)

Reviews

There are no reviews yet.