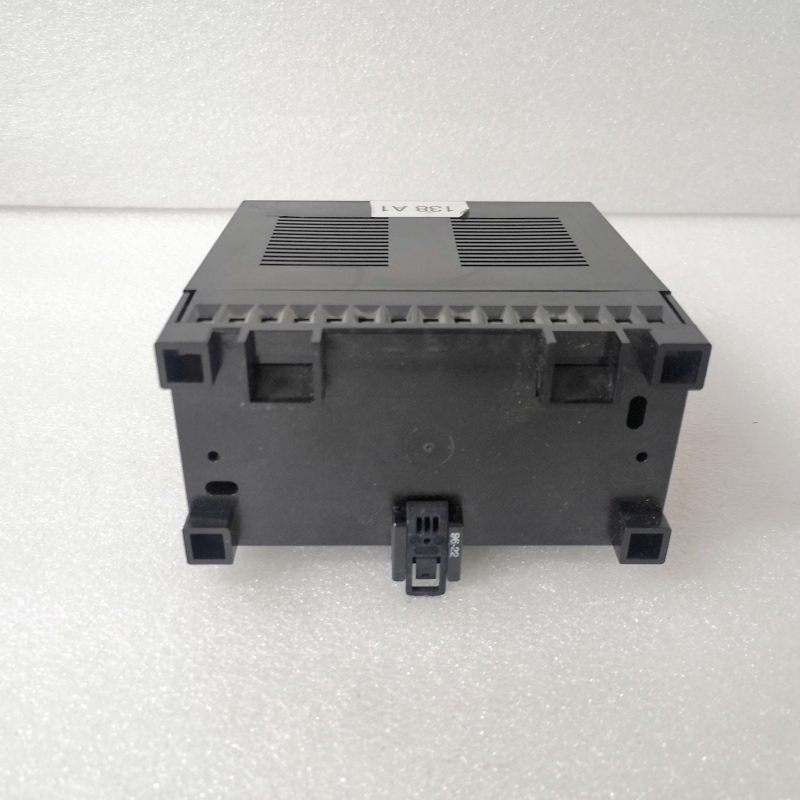

ABB ICSE08B5 FPR3346501R1012 control module

The ABB ICSE08B5 FPR3346501R1012 is a protection relay or control module, likely from ABB’s Relion® 650 series or a similar protection & control system.

·Tara(Sales Director)

·Tel: + 86-13806028623

·Whatsapp:+86-13806028623

·Email: ydf8801@163.com

·Ship to you via ·DHL/TNT/UPS/EMS/Fedex